Technological innovation is the core driving force for the development of the silicone industry. In recent years, remarkable progress has been made in technological innovation in the silicone industry. On the one hand, new silicone materials are emerging continuously. For example, the composite technology of silicone rubber with other materials is becoming increasingly mature. By compounding silicone rubber with nanomaterials, high - performance fibers, etc., new silicone materials with higher strength, better wear resistance, and corrosion resistance have been developed, expanding the application of silicone in fields such as aerospace and high - end equipment manufacturing.

On the other hand, the silicone production process is constantly being optimized. Traditional silicone production processes have problems such as high energy consumption and low production efficiency. With the application of new technologies, such as continuous production technology and automated control technology, the silicone production process has become more efficient and environmentally friendly. Continuous production technology enables silicone production to operate continuously, greatly improving production efficiency and reducing production costs. Automated control technology can accurately control various parameters in the production process, improving the stability of product quality.

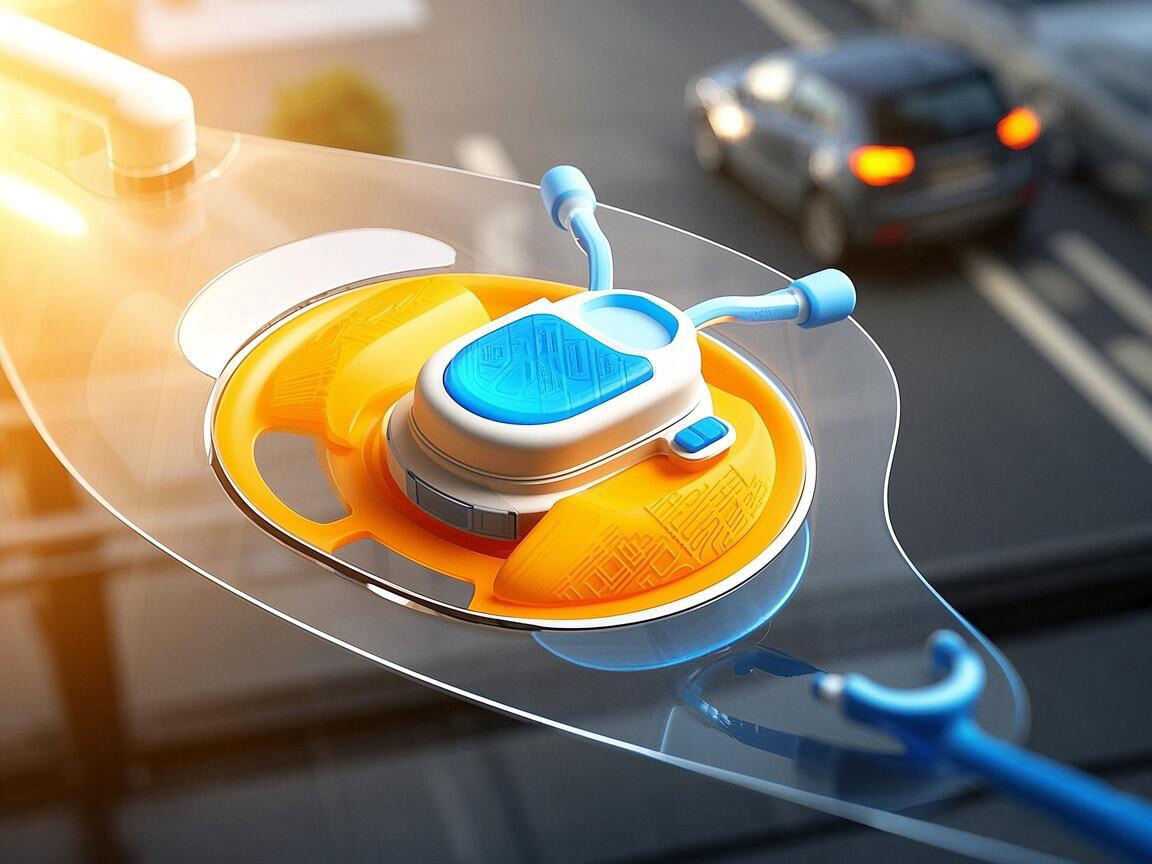

In terms of application expansion, with the rapid development of emerging industries, the application fields of silicone are constantly expanding. In the new energy vehicle field, silicone is widely used in battery systems, motor sealing, body damping, and other parts. In the battery system, silicone is used to make battery seals and thermal conductive materials, effectively preventing electrolyte leakage and improving the safety and heat dissipation performance of the battery. In terms of motor sealing, silicone can adapt to the high - temperature and vibration environment generated by the high - speed operation of the motor, ensuring the stable operation of the motor.

In the 5G communication field, silicone also plays an important role. 5G communication base stations have extremely high requirements for the heat dissipation and electromagnetic shielding performance of equipment. Silicone materials, due to their good heat dissipation and electromagnetic shielding performance, are used to make heat sinks, seals, and electromagnetic shielding materials for base stations, ensuring the stable operation of 5G communication equipment.

In addition, in the fields of smart homes and wearable devices, silicone has also become an ideal material for these products due to its softness, comfort, and environmental friendliness. For example, in wearable devices such as smart bracelets and smart watches, silicone straps are soft and skin - friendly, providing a comfortable wearing experience. In smart home products, silicone is used to make various seals and damping materials, improving the reliability and service life of products.